Think Green: Sustainability at WINTERSTEIGER

Machines, buildings, processes and relationships: WINTERSTEIGER takes a long-term view in all areas and consistently focuses on the future. The result is sustainability – for employees, customers and suppliers.

"Thinking about tomorrow" – for more than 70 years!

More togetherness

More togetherness

The whole is more than the sum of its parts (Aristotle). At WINTERSTEIGER, "Togetherness" has therefore been clearly defined as one of the seven corporate values. This value is put into practice through numerous joint activities for all employees, which are published every six months in the course book. More than 40 events are offered in the areas of Leadership, Team, Health & Care, Fitness, New Work, Communication, and Digital & Knowledge. Cooking, yoga and hiking together, as well as sharing knowledge through internal training courses, are particularly popular. Additional company events, such as Christmas parties, half-time parties and more, provide an opportunity to get to know each other and share experiences outside of the work environment.

Good, healthy, affordable

Our company cafeteria provides a healthy lunch every day. There are 3 different menus to choose from – from traditional home cooking to vegetarian and international cuisine. Most of the food we use comes from local farms. WINTERSTEIGER supports the communal lunch, which keeps prices low.

The "Regional & Xund" campaign with lighter menus for only 1 euro is particularly popular. WINTERSTEIGER covers a large part of the costs, thus raising awareness of healthy eating.

Important development goal: long product life

Whether plot combine, thin-cutting saw, ski grinding or straightening machine – WINTERSTEIGER machines are characterized by a particularly long service life: Some machines produced in the 1970s are still in use today. They can be modernized or upgraded, and spare parts are available. New developments use existing components wherever possible and appropriate. This approach ensures a reliable supply of spare parts for decades, extending the life of the product.

A second chance

Used machines are also in great demand – which is why WINTERSTEIGER operates a used machine center in each division. Machines are taken back, overhauled and returned to the market in order to conserve resources and avoid waste. Machines that can no longer be used are dismantled and the raw materials recycled.

Reliable to the end

In the best example of longevity, one of our first stone belt grinders from the 1980s was in use for 40 years at a sports shop in Hallstatt, Austria, sharpening skis right up to the end. It was only replaced by a new Omega in 2024. Our apprentices then overhauled the old TSMS-A, which is now on display in Ried.

Successful development project: ecological filler

In addition to thin-cutting saws, the Woodtech division also manufactures plants for wood repair: naturally damaged areas such as knotholes or cracks are repaired with a special filler, resulting in high-quality parquet flooring or furniture panels. In this way, the valuable raw material wood can be used even more efficiently.

WINTERSTEIGER has also succeeded in developing an ecological filler made from limestone and talc, the "Organic Filler". The mineral, water-based one-component material was specially developed for the requirements of machine processing in parquet production. It is suitable for all standard processing methods and surface coatings. It is applied cold and only needs to dry.

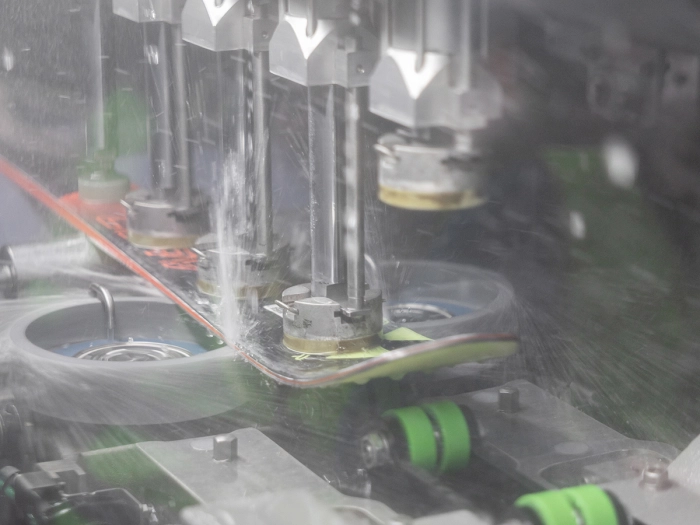

Jupiter: ski service system with environmental considerations

WINTERSTEIGER's ski service machines are environmentally friendly in operation, they score with their economical consumption of electricity and grinding water and are also very durable.

WINTERSTEIGER has succeeded in continuously reducing the power consumption of its ski service machines and currently produces the most economical machines on the market: The Jupiter automatic grinding machine consumes approx. 2 – 3 kW less power than machines from other manufacturers. This is due to a more efficient motor design, a more effective heating system when waxing the skis, and advanced temperature controls.

Grinding water with an extended expiration date

A synthetic coolant is added to the grinding water in ski service machines to cool skis and tools during the grinding process. The coolant also increases the biostability of the water and protects the metal edges of the skis and snowboards, as well as the components of the ski service machines, from corrosion. Together with the manufacturers, WINTERSTEIGER continuously adjusts the composition of the cooling lubricants to optimize their effectiveness. Unlike other manufacturers, WINTERSTEIGER uses synthetic cooling lubricants that are not based on mineral oil.

The grinding water is cleaned by single to multi-stage filters, the design and number of which are optimized for the respective ski service machine. During the summer months, the grinding water in the tank is additionally bio-stabilized by a micro-aerator, which further extends the service life.

GreenDry: energy-efficient condensation drying

In the "Dry & Protect" product range, WINTERSTEIGER offers solutions for drying, germ and odor reduction of workwear and turnout gear.

With a focus on minimizing energy consumption, WINTERSTEIGER has developed the energy-efficient "GreenDry" technology, which is used in the Econ drying cabinet.

The Econ model dries jackets, boots and gloves using condensation technology: the moisture in the heated air condenses on cold copper pipes in the cabinet. The water runs off along the pipes and is collected in a built-in sump or sent directly to the drain. To save additional energy, the heated air circulates in the closed cabinet and does not escape into the room. In addition, the air is heated by the heating elements only at the beginning of the drying process to reach the desired operating temperature. After that, the heating process is only restarted when the temperature inside the cabinet drops.

Conclusion: Thanks to GreenDry, the Econ drying cabinet consumes up to 60 % less energy than conventional models.

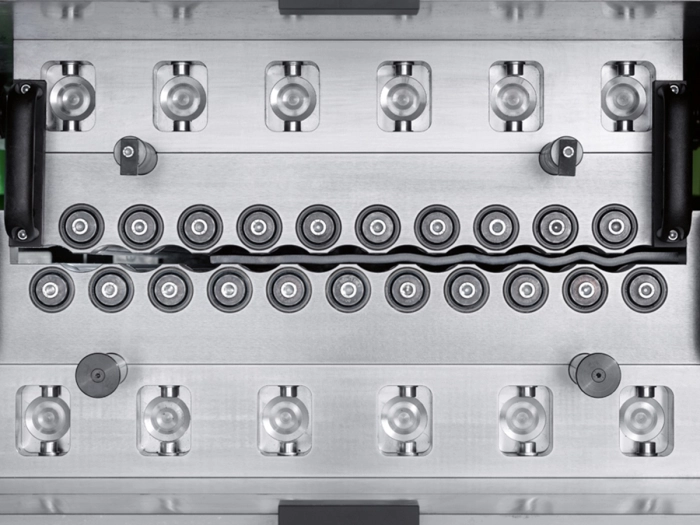

Leveling technology with a green twist

Cutting, punching, folding, bending, welding, assembling: Stresses in sheet metal play a decisive role in all areas of sheet metal processing. Together with the flatness of the blanks, they have a significant influence on all upstream and downstream production processes. Professionally levelled sheets are low in stress, have the required flatness and can therefore be processed optimally.

KOHLER levelers not only achieve optimum leveling results, but also score points for their environmental benefits. This is because all KOHLER part levelers operate completely without hydraulic systems. The result: low maintenance, no leakage, insensitivity to temperature fluctuations, higher energy efficiency and therefore improved environmental compatibility.

Thanks to the use of a direct drive for the leveling rolls and the electro-mechanical leveling gap control, which has been tried and tested for years, the Peak Performer part leveling machine from the 85P series upwards also outperforms conventional machines on the market with energy consumption reduced by up to 75 %.

The German company KOHLER Maschinenbau GmbH in Lahr has been part of the WINTERSTEIGER Group since 2011.

The Social Fund: ecological, social, and economic

We throw (almost) nothing away: discarded office furniture, parts of buildings after renovation, old wood from pallets, superfluous shelves and much more are auctioned off internally. The proceeds from these auctions go to the Social Fund, which was established as an association in 2016. Following a generous initial donation from WINTERSTEIGER, several thousand euros have since been collected. This money is used to provide financial support to colleagues in emergency situations. The process is straightforward and many colleagues have been helped quickly and without red tape. The Social Fund is ecologically, socially and economically successful – and thus perfectly covers the three dimensions of sustainability.

The support options include:

- Physiotherapy following a slipped disc or similar illness

- Psychological treatments

- Medical aids

- Hearing aids, vision aids, varifocal glasses

- Massage expenses to maintain mobility

- Therapeutic riding (e.g. disabled family member)

- Caregiving expenses for close family members

- Travel expenses to special therapies

Seed breeding equipment for a sustainable food supply

Seed breeding equipment for a sustainable food supply

Seeds need constant improvement: Climate change, soil erosion, population growth and new pests are all having an impact. Seed breeding is used to counteract these factors and to develop and adapt crop varieties such as cereals, corn, soybeans, rapeseed, etc.

WINTERSTEIGER provides the necessary machines, equipment and software solutions.

Successful plant breeding requires efficient products and innovative technologies, including automation and robotics, digitalization and special software solutions. WINTERSTEIGER offers complete solutions for customers worldwide, regardless of soil or climatic conditions – and thus contributes to a sustainable food supply.

Bike Services: Intelligent filter technology and efficient energy use

Bike Services: Intelligent filter technology and efficient energy use

Our Bike Services products contribute to sustainability wherever they are used. The focus is not only on effective cleaning of bikes and easy handling of the machines. Efficient use of available resources – in this case water – can make a big difference in everyday use. The fully automatic Velobrush uses a closed water circuit. The water is recycled through the use of filters and oil separators. Depending on the degree of soiling, between 50 and 100 bikes can be washed with just one tank filling. The manual Veloclean Pro washes with low pressure and hot water. This means that much less water is used than with high-pressure systems. In addition, the bike wash itself is much gentler. An oil separator in the Veloclean Pro also ensures that the dirty water does not contain environmentally harmful lubricants. The waste water can therefore be discharged into the sewer.

The careful use of resources is particularly important in alpine regions, which are heavily dependent on tourism. That is why we pay special attention to making our machines as economical and environmentally friendly as possible right from the development stage.

Electricity from our own photovoltaic plant

In March 2021, the first photovoltaic system with an area of 2,830 m², spread over 7 company roofs and an output of 300 kWp, went into operation. The new "Technik & Service Seedmech" building, which was completed in 2022, was also equipped with PV modules.

WINTERSTEIGER currently has a total output of 500 kWp and the company's entire base load can be covered by green electricity. For comparison: WINTERSTEIGER could supply 50 households with solar energy.

Heat supply from renewable energy

In 2017, the buildings at the WINTERSTEIGER site in Ried were connected to the geothermal network of “Energie Ried”. The environmentally friendly district heating from hot deep water supplies an area of 22,000 m2. Two gas boilers with an output of 1,200 MW and 750 MW respectively were replaced and dismantled.

In 2023, 1,954,980 kWh of heating energy have been be provided by geothermal energy. "The heating works wonderfully. We had to make some changes when we connected to the geothermal system because the new heating system is designed for low temperatures. However, maintenance is now very low," says Benjamin Hochholzer, Head of Facility & Service.

The geothermal network in which the local energy supplier “Energie Ried” is involved is the largest geothermal project in Austria. The town of Braunau and the municipality of Simbach have been supplied with district heating since 2000, the town of Ried im Innkreis and other surrounding communities since 2012.

Utilizing heat return

The Seedmech Service & Technology building, constructed in 2022, is uses recovered heat from the surrounding production buildings. This innovative solution is providing an additional building with environmentally friendly heating energy provided by the geothermal network.

More heat, less cost

The low-temperature heating system (concrete core activation) heats an area of 1,500 m² with a return temperature of only about 60 °C. The heating capacity required in the Seedmech building is 110 kW – this additional heating system did not have to be installed.

In addition, the lower return temperature reduces overall heating costs: the lower the return temperature to the geothermal network, the lower the district heating tariff.

Energy-efficient hall ventilation

The mechanical production and the surface coating areas are air-conditioned and supplied with fresh air via a highly energy-efficient ventilation system. The aim of the investment was to create a better production environment for the employees.

The ventilation works on the principle of heat dissipation: the heat load generated is captured under the ceiling and dissipated via the roof. Cooler fresh air is introduced draught-free through textile hoses or displacement air outlets (infinitely variable, temperature controlled).

The ventilation system not only cools the hall, but also provides a constant supply of fresh air: The typical smell of coolant emulsion in mechanical production has completely disappeared, and the working environment for employees has been significantly improved.

Project "Company Bike": WINTERSTEIGER supports active mobility

Since April, WINTERSTEIGER employees have been able to lease a new bicycle on attractive terms: In the first four weeks of the project alone, 60 colleagues opted for a "Company Bike". The Company Bike is an opportunity to use a high-quality bike – be it an e-bike, mountain bike, racing bike, trekking bike or city bike – at a very reasonable price. The monthly payment is deducted directly from your gross salary: This salary conversion reduces the tax base for income tax and social security, so employees make additional savings.

Insurance and service are also included: if something breaks down or the battery stops charging properly, for example, this is included in the leasing contract, as are annual service works (e.g. adjusting the gears or checking the brakes).

Environmentally friendly and healthy

With the company bike, WINTERSTEIGER focuses on active mobility, because cycling keeps you fit and is environmentally friendly. Cycling helps to reduce air pollution and greenhouse gas emissions.

More than 130 e-cars at WINTERSTEIGER

More than 130 e-cars at WINTERSTEIGER

The mobility project "Social Car" is a complete success: since the last delivery, 100 employees have been driving an e-car sponsored by the company. They can choose between the VW ID.3, Cupra Born and Fiat 500e models. Including the electric company cars, the company already has more than 130 e-cars – this means that every sixth WINTERSTEIGER employee drives an electric car. The company car offer applies to all employees at the 7 locations in Austria: in addition to Ried, there are the locations in Mettmach, St. Martin, Vienna, Altach and Bartholomäberg in Vorarlberg as well as Liezen in Styria.

The number of charging stations on the company premises is being continuously expanded in parallel with the vehicle fleet: there are already 20 e-parking spaces with 22 kW, and a 150 kW fast charging station was recently put into operation. WINTERSTEIGER has expanded the existing photovoltaic system at the company headquarters in Ried to currently 500 kWp in order to sustainably cover the power requirements for e-mobility.